Latest News

The Mount Maunganui Industry Environmental Accord has been signed by 31 businesses within the industrial zone who have volunteered to take measures above and beyond what’s required to measurably reduce environmental impacts. We get an update from C3 Pedersen Group, an Accord signatory, about its work around reducing emissions and enhancing safety at Port of Tauranga.

The company

C3 Pedersen Group, one of New Zealand’s leading forestry and logistics service providers, evolved from the Mount Maunganui and Tauranga Stevedores, formed by Sir Bob Owens in the early 1950s – it’s now the longest serving log marshaller in the country. Over the past 75 years, it has expanded its log marshalling and stevedoring operations to most major ports across New Zealand, handling approximately 10 million JAS per year, which equates to ~28 million logs. C3 Pedersen Group employs around 500 people in the Tauranga / Mount Maunganui operations.

Committed to innovation, C3 Pedersen Group is working to redefine industry practices, delivering measurable improvements in both safety and environmental performance.

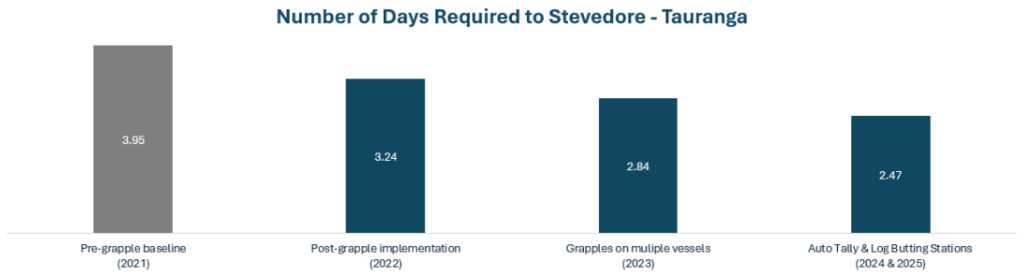

Achievements include the development of COM3Ts (an industry-first semi-automated log scaling system), the deployment of the award-winning Log Vessel Grapples (a mechanised loading solution that can be operated from a ship’s crane), and more recently the Auto Tally and Log Butting Stations, which have reduced the number of staff and equipment operating in high-risk areas.

For the Port of Tauranga, the implementation of these initiatives has steadily reduced the number of days C3 Pedersen Group requires to stevedore a typical log vessel. Reducing ship time in port means a reduced burn of ship fuel, as the cranes are working for a shorter period and each ship spends fewer days in port. “Our innovation journey has seen investment in flexible, easily transferable solutions driving greater safety for our people, improved environmental outcomes and better efficiency for our customers,” says Gavin Hudson, CEO of C3 Pedersen Group.

The challenge

A current focus is ensuring machinery within the port operates at safer speeds, contributing to reduced fuel consumption and lower emissions.

During any given shift, the company could have up to 30 log loaders, material handlers and terminal tractors in use within its Mount log marshalling and stevedoring operations. Understandably, a fleet of this size consumes a considerable amount of fuel, which in turn produces unwanted emissions. A sustainable intervention was required to enable these machines to operate at lower fuel consumption without impacting operational performance.

The intervention

In Q4 2024, the team conducted trials to fine-tune the engine speeds of several material handlers in the Mount Maunganui fleet (photo at top). The trial concluded there was no material decline in performance, but there was a ~30% decrease in fuel consumption on the one machine studied in detail. (The team is now digging deeper into the results to identify the optimal engine speed that could further reduce fuel usage on other machines in our region and countrywide.)

The focus then shifted towards improved management of machine travel speed. In Q2 2025, the team began governing the maximum speed on all log loaders (photo below) and terminal tractors through telemetric and mechanical controls. The results showed that consistently lower speeds led to consistently lower fuel consumption.

The impact of this change on four heavy log loaders monitored in detail has meant a fuel consumption reduction of about 3 litres per hour. For these four machines alone, this translates to the removal of roughly 12T of CO2 per month from the Mount Maunganui operation. This change is now being rolled out to all applicable machines across the country to further reduce CO2 emissions.

While significant strides have been made, the group says it will continue to look for smarter, safer and more sustainable ways of working.

Priority One will continue to report on other notable progress in the industrial zone, so to keep up to date with these stories, along with other news on sustainability, innovation and infrastructure, sign-up for our fortnightly newsletter here.